-

Email-Id: info@kjinsulation.com

-

Call Us: +91 9970 736 083

Email-Id: info@kjinsulation.com

Call Us: +91 9970 736 083

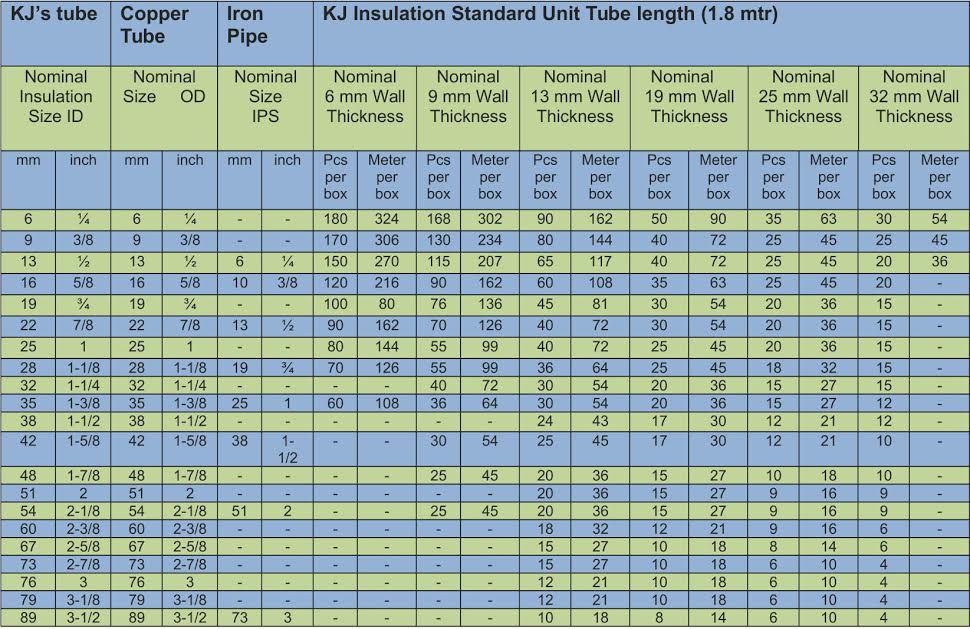

KJ pipe insulation is an environmentally friendly CFC free, flexible elastomeric thermal insulation. It is available in a wide range of colors. With smooth shark skin and is available in unslit form in wall thickness of ¼”, 3/8”, ½”, ¾”, 1”, 1-1/4” in sizes ranging from ¼” ID to 4-3/8” Iron Pipe size. KJ Insulation pipe is non-porous and resist mildew growth.

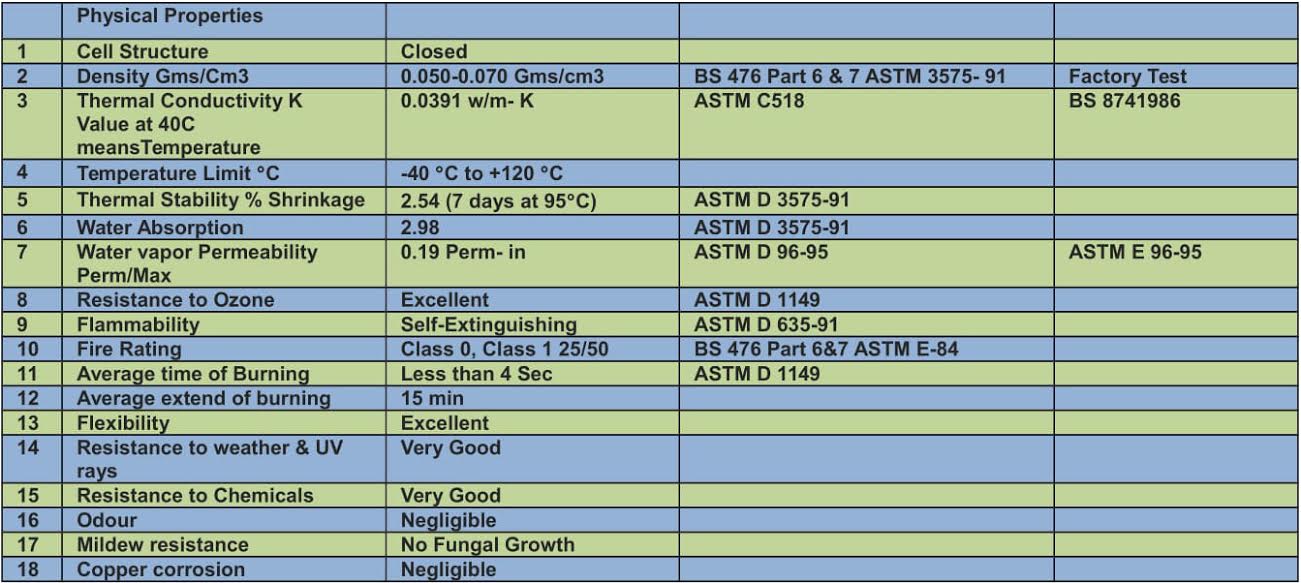

KJ Insulation is used to retard heat gain and prevent Condensation or frost formation on refrigerant lines, cold water plumbing and chilled water systems. It also retards heat loss for hot water plumbing, liquid heating, dual temperature piping and many solar systems. KJ Insulation is recommended for application ranging from -40C to +120C. The expanded closed cell structure makes an efficient insulator and an effective moisture vapour retarder. KJ Insulation has a very tough Shark & glossy Skin which withstand tearing rough handling and severe environmental conditions. And yet is quite flexible for easy installation. KJ Insulation has superior cold weather flexibility. KJ Insulation can be used with heat tracing/heat tapes. Cut tubular sections, cover fingers, etc. From our KJ Insulation Sheet.

With a factory applied spray of talc on the smooth inner surface, KJ Insulation Tubes slides easily over pipes or tubbing for quick installation. When applied to existing lines, tubing is split lengthwise and snapped into place. (Slitting can be done on the job with a sharp knife. All seams and butt joints should be sealed with an approved contact adhesive (KJ Insulation is available on request) making sure both surfaces to be joined are coated with adhesive.

KJ Insulation is made from a UV resistant elastomeric blend, for moderate UV exposure applications, no additional protection is needed. However, for severe UV exposure applications (rooftop application) or where optimum performance is required, an approved UV protected coating or appropriate jacketing or cladding should be used. For best appearance two coats are recommended.

For buried line above the water table use a clean fil such as sand (3”-5” layer) to project KJ Insulation before back filling. It is recommended that materials to be buried are properly sealed at all seams and butt joints with an approved contacts adhesive. For optimum performance, the line should be conduit to protect them from problems associated with ground water.

The closed-cell structure and unique formulation of KJ Insulation effectively retard the flow of moisture vapour and is considered a low transmittance vapour retarded. For most application, KJ Insulation needs no additional protection. Additional vapour barrier protection may be necessary for KJ Insulation when installed on low temperature surfaces that are exposed to continuous high humidity.